Horizontal High-Speed Machining Saves Hundreds of Work Hours

By: Evan Doran

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Kicking RaaS with Robotics as a Service

By: Julia Hider

Robotics as a service (RaaS) enabled Behrens Manufacturing to quickly address a severe worker shortage while maintaining its ability to invest in new metal forming equipment.

Metalworking Activity Contracts With the Components in June

By: Jan Schafer

Components that contracted include new orders, backlog and production, landing on low values last seen at the start of 2023.

#economics

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Zillow for Machine Tools?

By: Brent Donaldson

The ability to see spec-by-spec comparisons between machine tools made Techspex.com immediately popular. Now, the machine tool search engine boasts a fresh new look and 5 must-see upgrades.

#thesetup

World Machine Tool Production and Consumption Modestly Down in 2022

By: Jan Schafer

While global machine tool activity slid back to 2020 levels last year, overall production and consumption were still at historically healthy levels.

Shop Quotes Smarter, Works Harder with Machine Monitoring

By: Evan Doran

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

You Are Not Spending Enough on Gaging

By: Peter Zelinski

Is there an intuitive ratio shaping shops’ perceptions of how much gaging capacity is appropriate for their machining capacity? Much has changed; that ratio might need to be reconsidered.

#zaxis

Give Job Shop Digitalization a Customer Focus

By: Mark Albert

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

CNC-Related Features of Custom Macro

By: Mike Lynch

CNC-related features of custom macro are separated into two topics: system variables and user-defined G and M codes. This column explores both.

#cnctechtalk

Modern Machine Shop Celebrates 95th Anniversary

By: Modern Machine Shop Editorial Staff

Staying adaptable and leading through change for 95 years and counting, Modern Machine Shop celebrates its 95th Anniversary since its first publication in 1928.

Combining Multiple Probes: A Recipe for Success

By: George Schuetz

Combining measurement techniques enables a wide range of relational characteristics to be measured with just one or two sensors.

#qualitygagingtips

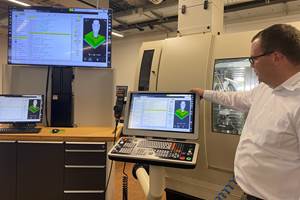

Manufacturing Technology and Training in Europe

By: Julia Hider

NTMA’s European Tech Tour exposed attendees to the latest technology and traditional training methods used by European manufacturers.

#workforcedevelopment

The Impact of Cutting Teeth Spacing on Machining Stability

By: Tony Schmitz, Professor, University of Tennessee, Knoxville | Joint Faculty, Oak Ridge National Laboratory

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

By: Evan Doran

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.