By pairing a Productive Robotics OB7 cobot with this Haas DS-30Y, Above All CNC can now machine 10 to 15 of these parts for bear-resistant containers overnight.

When campers and backpackers are out traversing the wilderness, many public spaces require bear-resistant canisters to protect food and other scented items from bears. In order to get approved for use at destinations like Yosemite, these canisters must undergo testing that includes a trial where live bears are given a certain amount of time to break into a canister.

Parts for a line of these canisters are manufactured at Above All CNC, a Goleta, California, machine shop founded in 2016. Much like how bear-resistant canisters are refined for better quality if they don’t pass certification testing, the machining processes and data tracking for these parts have been refined by Above All to remove production bottlenecks and reduce scrap rates.

Featured Content

Bearing Down on Efficiency

Tim Rousseau, founder and owner of Above All, first encountered these bear-resistant canister parts about 20 years ago when he worked for a different company. To make these parts, the company ordered aluminum rod stock or round bar and cut them up with a saw, sent them out for trepanning as well as double-disc grinding and brought them back to the shop to run through several lathe and mill operations.

The final part of the process was to tumble finish the parts, which typically took around three to four hours for a batch of 20 parts — and sometimes less when working with the larger round parts for these canisters. With a typical order consisting of 250 parts, this method created a bottleneck in production, in addition to high scrap rates, because parts could still come out with scratches or other cosmetic features the customer didn’t like, such as water spots from the rinsing process.

“The biggest bottleneck eventually became the tumblers, so we needed to speed that process up or eliminate it entirely,” Rousseau says.

A completed bear-resistant canister machined by Above All CNC, with an appearance from Stella, the resident shop dog.

Shortly after Rousseau left his previous company to start Above All CNC, the bear-resistant canister customer found him and asked if he wanted to bid for production of those parts. Despite the aches and pains the parts caused with the previous process, Rousseau had a vision for how he could make them more efficiently.

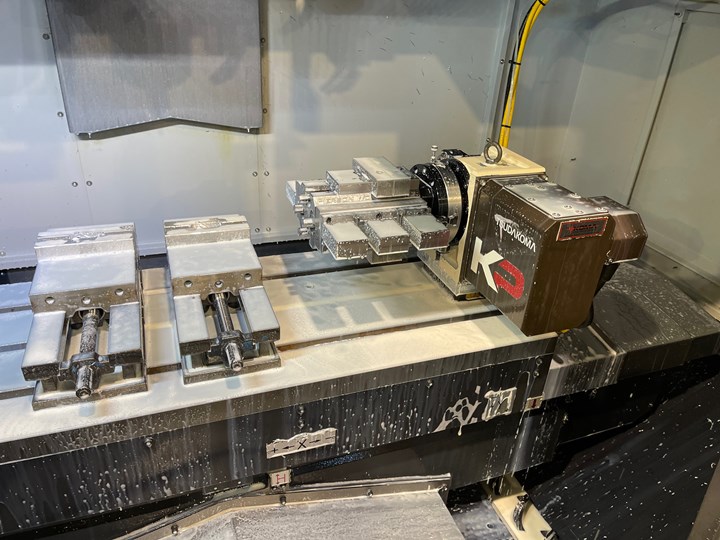

The solution he came up with was to produce the parts in a Haas DS-30Y with live tooling. The shop buys the round bar, cuts it on a Hydmech saw, stacks it all on one pallet and brings it to the lathe to machine it completely in a single operation. The deburring is done inside of the machine, which cuts out the tumble-finishing process that caused most of the bottlenecks in the previous method.

The machine is now paired with a Productive Robotics OB7 cobot to automate the process. With this cobot, Above All can now load up a pallet and machine 10 to 15 of these parts unattended per night.

Total cycle time for the canister parts is now about an hour, while order lead times and scrap rates are reduced by eliminating additional machining operations, and cutting out the now unneeded outsourced and internal processes such as tumble finishing and rinsing.

You’re Going to Have to Figure This Out

The commitment to creating more efficient processes is something Rousseau picked up on when he first started working as a welder in the previous shop after he studied welding in community college.

“I learned how to take pride in my work at that point and was the lead welder for about a year,” Rousseau says.

Then, in early 2009, he showed up to work at the shop and no one else was there. The owner had laid off everyone else due to the blowback of The Great Recession. Rousseau says he was only making around $10 an hour at that time, so the owner kept him around and had him learn how to run everything in the shop.

“It was just the two of us, so he gave me access to the programming software and essentially told me, ‘You’re going to have to figure this out,’” Rousseau says.

With a relative lack of machining education resources online back then, Rousseau began to teach himself programming through trial and error, learning different functions and plugging things in until he got the results he was looking for.

This wasn’t unfamiliar territory for Rousseau, who spent a lot of his childhood tinkering with things and taking them apart to see how they work. Coming from a long line of engineers, Rousseau took on a variety of technical projects growing up, with the help of various family members. When Rousseau couldn’t afford a speaker cabinet for his bass guitar as a teen, he and his grandfather built one by going through catalog pictures and drawing up their own designs.

This ingenuity is still on display in portions of the shop. Rousseau didn’t want to share too much detail about the concoctions he has designed, but one workstation is equipped with a bass drum pedal from Amazon. Another uses a broom holder and parts he found on a cake maker’s website.

Trusting the Pros

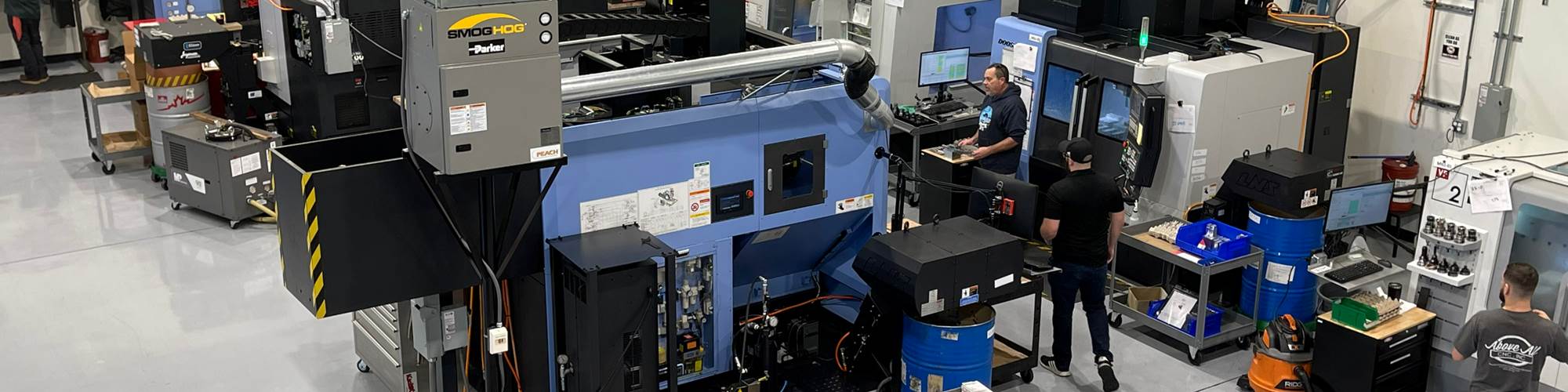

Although he has always been comfortable learning on his own, Rousseau still emphasizes the importance of leaning on knowledgeable resources to find success. That’s how Above All implemented its current shop management software setup with ProShop ERP.

Above All not only machines parts for the bear-resistant canisters but also machines parts for NASA solar arrays, such as the ones that were deployed over the International Space Station in June 2021. The need to keep track of jobs across the shop made Rousseau look at ProShop as a software solution.

This set of aerospace parts is set up in a Doosan DNM 4500S.

Once the shop implemented ProShop, Rousseau found that he could use the software for far more than just keeping track of jobs. He recalls having machinists manually fill out paper timesheets with information about when they were working on a machine and clocking in and out of jobs. This created clutter with scattered, scribbled time sheets, and Rousseau had to manually calculate whether the shop was actually hitting its quota.

Now, with ProShop, all of that information is tracked on kiosks at each machine. This new approach has worked so well that Rousseau wishes the shop had begun using it sooner, especially when his son was born right before the COVID-19 shutdowns.

“I was out of commission because I had a newborn at home, and my wife and I were a bit nervous. We didn’t know what was going on. So, I was working from home a lot, and it became apparent that I needed more visibility, even if it’s remotely,” Rousseau says. “I wish we had all of this set up at that point. It would’ve made it a lot easier to understand what the heck was happening in my business. The feedback loop of time tracking against jobs has been one of the biggest benefits resulting from the implementation of Pro Shop.”

A key part of making this work effectively was trusting the implementation specialists at ProShop and heeding their advice. Rousseau credits ProShop’s team for being comprehensive and setting Above All up for success.

“I had to concede and load up my shopping cart with the stuff they suggested and then pull the trigger,” Rousseau says. “They’ve already done all the hard work of figuring out what all those things are. You’ve always got to team up with people that are smarter than you or have more experience, and they have a vast amount of experience.”

Inspect the Technique

The previous challenge of documenting data manually led not only to Above All implementing ProShop but also to Rousseau’s realization that the shop also needed software to extract inspection data more efficiently for tight-tolerance aerospace parts. For this, he turned to High QA after talking with some representatives at the 2018 International Manufacturing Technology Show (IMTS).

High QA is integrated with ProShop, and Rousseau says the two softwares have cut down on inspection planning time, as well as shopfloor inspection time since manual data tracking and documentation are once again eliminated.

“There have been countless times in the past that we’ve been documenting in-process inspection data and could very well be writing down the wrong thing all day, ultimately making scrap. There was nothing to prompt operators or stop production,” Rousseau says. “Utilizing Proshop and the digital in-process checks, if you enter a bad dimension, it immediately alerts you to create a non-conformance report. So, it’s like, hey that’s not good. What are we going to do about it before you continue making parts?”

With ProShop ERP kiosks at its machines, Above All CNC no longer needs to perform data entry by hand, and with High QA and ProShop, operators can inspect parts at these kiosks.

With this setup, operators are able to inspect parts at the machine and enter the data into one of the kiosks. For acceptable quality limit (AQL) inspections on high part quantities, the shop uses High QA and ProShop to quickly detail which dimensions will be checked by operators at machines and which are checked by QC. This process has turned inspections that used to take several hours into inspections that take less than an hour.

“It saves copious amounts of time,” Rousseau says. “It’s ridiculously helpful. I’m not sure how anyone gets by without it. With all the complexities that come with generating an aerospace first article inspection, it really holds your hand through the whole process and makes sure it’s done per the standard. It’s just a no-brainer for us.”

With new machining processes and more automated, organized data tracking, Above All can now rely on its newfound efficiency to complete its jobs. To enjoy the fruits of this laborious process, Rousseau was able to watch the solar array deployments with his five-year-old daughter — who he says is obsessed with all things space — on Father’s Day in 2021.

“They scheduled the deployment of the solar arrays on a Sunday morning, so I woke her up early and asked, ‘Hey, do you want to watch the spacemen use all of Daddy’s parts that we made on the machines?” Rousseau says. “And she was really excited about it, so that was definitely rewarding. It’s extremely entertaining and satisfying to watch these astronauts live on TV, bumping their helmets into parts that you’ve made and helped contribute in a large part to the design for manufacturability.”

RELATED CONTENT

-

When Evaluating Gage Stability, a Picture Says 1,000 Words

Gage capability programs can help analyze the cause of stability problems, but it can be revealing to manually sketch out histogram data to get a pictorial view of what is happening.

-

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

-

How to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

.1692800306885.png)

.1687801407690.png)