During shop visits, Modern Machine Shop editors have gotten used to seeing rows of people huddled over benches with spotlights, scopes and hand tools. In fact, the sight is so common that the odd juxtaposition of tedious manual work and sophisticated, automated CNC machining processes can be easy to overlook.

Video games inspired the solution to automating tedious, manual grinding and chipping of large castings for stamping presses and other metal-forming machinery. All photos courtesy of ATI Industrial Automation, MESH Automation and/or Nidec Minster.

However, recent evidence suggests that many of these manufacturers might benefit from considering (or reconsidering) what a robot can accomplish. This was the subject a video interview with Dan Merritt, material removal product manager at robotic end-effector manufacturer ATI Industrial Automation, on the 2020 IMTS Spark platform.

Featured Content

Although the interview was virtual, the two applications Merritt used to demonstrate the promise of material-removal automation are real. In fact, these same two applications would be focal points of another presentation hosted by ATI and the Association for Advancing Automation (A3), an industry trade group, just a few weeks later as part of the Automate Forward event, this time with testimony from the end users themselves.

Assumptions about what is or is not possible to automate are often misplaced.

The reason for ATI’s focus on these particular case studies is simple: Both stand out as examples of the value of early proof-of-concept testing — a service that the company now offers from dedicated laboratory space — prior to making significant investments. Taken together, the two projects also illuminate a number of common elements underlying the successful application of increasingly accessible technology for work that should be a natural (if elusive) target for automation. “I can’t think of an application space that better embodies dull, dirty and dangerous,” Merritt says about material removal.

Grueling Deburring to “Video Game” Robotics

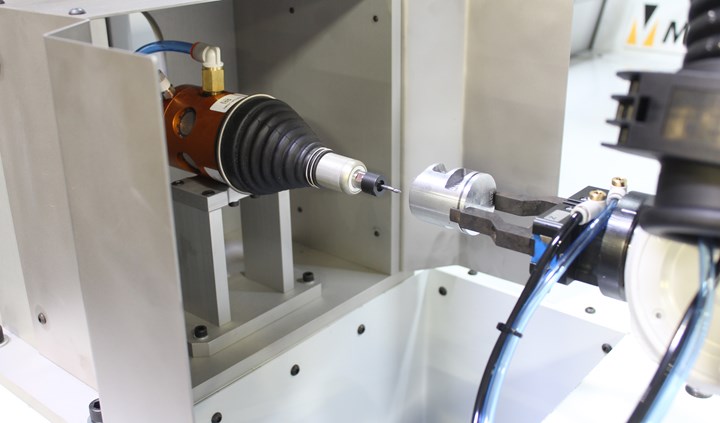

One application involves the kind of deburring that MMS editors see regularly, with the notable exception that robots are doing the work rather than people. Specifically, the robot picks freshly machined automotive pistons from a staging fixture and presents them to the deburring tool (ATI’s radially compliant RC-300). As the robot maneuvers, the tool moves with it “like a joystick,” Merritt says, leveraging its pneumatic internals to apply constant, user-defined pressure to the shifting geometry pushing back against it.

Jim Webb, sales and marketing director at automation integrator MESH Automation, says capability to adjust air pressure dynamically was critical to designing the system. This enabled applying different levels of contact force for two different finishing tasks: removing flash leftover from the aluminum casting process, and cleaning burrs nestled within a CNC-turned groove. Although the previous method – electric hand tools – had been moderately successful, time savings and a safer environment for employees justified the automation.

Holistic thinking is evident in the design of pre-configured automation cells and the use of multiple robots for processes including machine-tending, deburring and inspection.

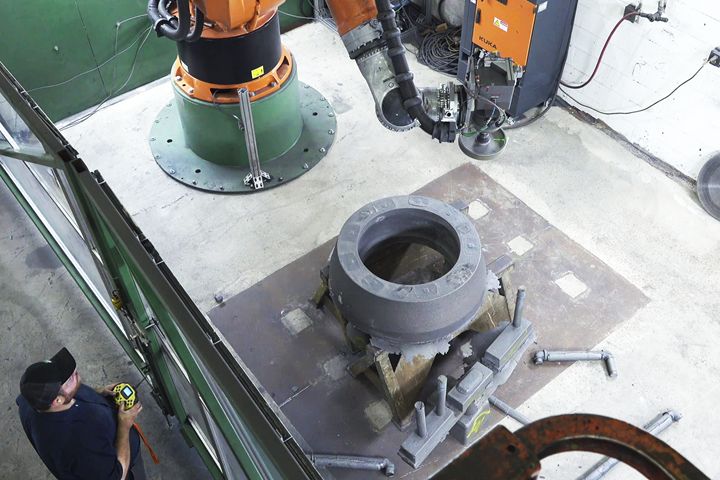

The other application is a more extreme example, in terms of both the nature of the job and the reasons for automating in the first place. Ductile iron structural components for the stamping presses and other metal-forming equipment manufactured by Nidec Minster can weigh as much as 25,000 lbs. Before automation, de-flashing, de-gating and otherwise removing remnants of the casting required wielding vibrating, handheld grinders that could be as heavy as 20 lbs. There were no rows of people huddled over benches in this case, but the risk of compromise to workplace health and safety was no less significant.

The robot speeds material removal with force levels that exceed that of any human, but the ductile iron components require custom tooling.

The task would be difficult. Batch sizes varied, as did removal requirements from batch to batch. Meanwhile the massive size of the parts made fixturing and access to critical features difficult. Success depended on practiced hands, as well as a subjective feel for the right level of pressure to apply at any given point along tool paths that had proven highly impractical to program. Nonetheless, the need was great enough that management was “open to out-of-the box ideas that let engineering dream up different types of solutions,” recalled Nidec’s Johnathan Rankin during the A3 presentation.

As depicted where, the massive robot arm that now brings the tool to the part is guided by thumb, as if the operator were playing a video game. Like a game, controller vibration makes collisions seem real — and in this case, they are. Thanks to an ATI Omega191 force/torque sensor, which translates signals from an internal strain gage into the data that drives haptic feedback, operators can “feel” their way through the grind, adjusting as they go. The system “marries the brute force and brawn of a robot with nuance and skill of human operator,” Merritt says.

Different Proofs, Same Lessons

Merritt says he and his colleagues at ATI had never envisioned using the sensor to provide feedback to a person rather than a computer. However, this is precisely the kind of development that they expect to come from the company’s new lab, which was set up specifically to enable applying ATI engineers’ deep tooling expertise in the context of the entire, automated process. The end game is to make automation more accessible, both for integrators like MESH determining whether and how to automate or an end-user process developer seeking CapEx approval. “We’re not going to provide code or a recommendation on a cell layout, but (we will provide) proof of concept and advice based on own experience and testing and make this less intimidating,” Merritt says. “Most of the time, customers want to see ‘How did you program it? Can I see and touch the parts?”

“Don’t let the ideal or perfect state become the enemy of the good. – Dan Merritt, ATI Industrial Automation

MESH has significant testing resources as well. As for Nidec Minster, few laboratories could accommodate the large parts. Nonetheless, the company’s approach also emphasized due diligence and early, thorough prove-outs of key concepts. Specifics aside, all three companies – a technology supplier, an automation integrator and an end user – view this early, thorough prove-out as an essential early step toward determining whether and how to automate. Taken together, their testimony reveals a number of lessons that are likely broad enough to translate to most material-removal applications. These lessons include:

The Past is (Only) a Guide. The piston-deburring application employs MESH Automation’s Mini-MAC platform, a small-format version of its MAC (MESH Automation Cell) systems. MACs are pre-engineered robotic modules meant to streamline the integration process (much of the wiring, guarding, tooling and everything else the robot needs is already assembled). With each new job, “We look at what worked in the past and reexamine ways to modify methods for new applications,” Webb says.

Although the piston-deburring automation is similar to other systems configured over the years by integrator MESH Automation, the company still took advantage of ATI’s tool leasing program to thoroughly test the deburring tool.

However, thorough testing of new jobs is no less important. In one recent application, the elements of the process were all “pretty traditional,” he recalls – that is, the company had seen and dealt with all the variables presented by this application before. However, digging further revealed an “impossible-to-manage range” of part variation. “Had we not tested, and (had we) simply taken an order to build something, we probably would have wasted a lot of time and money.”

Focus on outcomes. Early goal setting is critical, and unrealistic expectations can stymie any automation effort. Merritt says ATI collects reams of application information early, prior to any testing, then consults closely with customers to ensure the data on drawings and other documentation matches the reality of what they hope to achieve. “You have to agree on expectations,” he says. Barring specific pass/fail criteria, narrowing down the “must-haves” and “nice-to-haves” can help “shape the spectrum of options” for achieving consistent, repeatable finish.

An “all-or-nothing” mentality is a relatively common barrier to automation, he continues, particularly among those who are new to robotics. Many manufacturers “want to go from 100-percent manual to automated everything,” he explains. Timelines stretch, costs surge, and “the business case falls apart.” He recommends “taking a step back.” Automating a portion of the process – “taking 10 people doing manual deburring all the way down to three” – is better than nothing. “Don’t let the ideal or perfect state become the enemy of the good,” he advises, particularly when presented with opportunities to break bottlenecks or reduce scrap.

Start with the part. MESH’s approach to most projects sounds similar to how a machinist might work through a complex setup for a single machine tool – that is, by examining how part and tooling interact in order to establish the best locations for fixturing datums. “Once you know how to control it, you figure out how to work it,” Webb says. “Each project involves a balance of datum control, material removal rate, expected cycle time, expected surface finish – we focus on controlling these variables and the path of the robot to do what we need to do.”

For Nidec Minster’s application, part size and variation made any system that relied on fixturing prohibitively expensive (Rankin noted during the A3 presentation that the company had experimented with and ruled out the use of vision systems to align part and robot). Still, the team began with the interaction of tool and part – the core of the process and the core of their expertise.

Consider all paths to prove-out. The foundry team recognized that the abrasive materials employed for manual grinding would likely be too soft for the forces exerted by the robot. However, it took the experience and recommendation of a trusted, outside supplier to identify the right tool for the job: a diamond-coated, steel-hubbed wheel that Rankin says is “key” to the entire process. “Nobody wants to go down the road of custom tooling, but when our abrasives partner said this was the way to go we had to trust them,” he recalled. “We’re really glad we trusted them with that.”

Also critical to concept prove-out was the input of the supplier of the military-grade wireless hand controller, WHO? which had never before been employed to guide an industrial robot. “They really helped by developing a custom communication protocol to communicate with an industrial robot instead of a tank or a drone,” Rankin says. “There were lots of examples in this specific project where we couldn’t test a lot of variables beforehand, so we focused more on identifying and building relationships with our suppliers. Their comfort level and individual experiences became extensions of ours, and that let us confidently move forward.”

Think holistically. Nidec Minster now markets its new automation system, which it calls ExoGrind. One key selling point is that the system was designed to work with a variety of application requirements. For example, rather than fully manual control, an operator might use a laser guide to thumb the robot into proper alignment with the casting, then call up a canned subroutine. At higher volumes, the Omega sensor might facilitate full automation by acting as a force-control device rather than a force-feedback device. Another spin on the same concept, ExoGuide, uses the controller and programming for non-material-removal applications.

New laboratory testing services and new tool varieties, such as this robotic sander developed in partnership with 3M, reflect the company’s expanded focus.

“What else can that robot do?” is a question worth asking on the level of individual processes, too, Merritt says. For example, a system already employed for pick-and-place or CNC machine-tending operations might also bring parts to a cleaning station. Likewise, Webb says MESH considers material removal to be “just one step in the overall flow of a part through a process.” In the piston-deburring application, the robot cycles through both inspection and laser-engraving operations. Meanwhile, another arm that tends the lathe is mounted on a slide, thus enabling the system to serve a varied number of machine tools.

Think adventurously. Rigorous, early testing of core capabilities is often valuable for checking assumptions about not just the limits of automation, but also the possibilities. Assumptions about what is or is not possible to automate are often misplaced, and ideas can spring from the unlikeliest of places. At Nidec Minster, “We all laughed” when someone first suggested hand-held, wireless robot control, says Rankin, who is now the company’s Robotic Automation Sales and Engineering Manager. “We started talking more about ‘Call of Duty’ than what we were there to talk about, but as we kicked around the idea, we recognized that it would address a lot of our issues.”

RELATED CONTENT

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

-

Inserts For Difficult Materials

Economic efficiency is an important consideration when choosing tools for challenging metals.

-

Threading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

.1692800306885.png)

.1687801407690.png)