Cross-hole Deburring Tool Eliminates Secondary Process

The Orbitool from J.W. Done helped Paramount Machine eliminate a secondary deburring process, saving 75 process hours across a 2000-part run and enabling the shop to meet its profit and delivery time goals.

#casestudy #Basics

Edited by Evan Doran

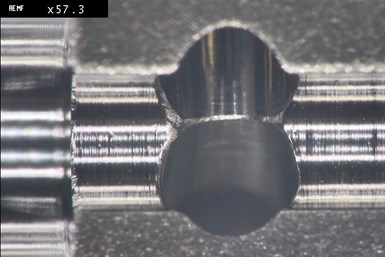

J.W. Done’s Orbitool uses a disk to shield properly finished parts of bore holes, falling away from the wall at the intersection between holes to enable the cutter to proceed with targeted deburring.

Photo Credit: Paramount Machine

Cross-holes have long been an Achilles’ Heel for subtractive manufacturers. As editor emeritus Chris Koepfer of Production Machining once wrote, “despite the best efforts of machinists and programmers, burrs are virtually impossible to eliminate when cross-drilled holes intersect.” In many cases, shops must take an “as good as it will get” approach with parts featuring cross-holes to prevent overlong cycle times that risk customer confidence.

Paramount Profits

Paramount Machine, a job shop in Salt Lake City, Utah, is familiar with this dilemma. During one job with 2000 parts that featured cross-drilled holes for a commercial aerospace application their they found that producing the parts required 185 hours of machine time, with an additional 120 hours in the foreign object debris (FOD) room to deburr the parts.

Featured Content

The deburring process time stressed Paramount’s ability to meet its delivery dates with the client, and, worse, the difficulty of successfully deburring these cross-drilled parts led to rejections from the customer due to remaining burrs or uneven deburring. While Paramount did improve its process over the first job runs, the shop wanted to improve its process.

Using Orbitool increased on-machine cycle times by 45 seconds per part — but decreased time required in the FOD room by about three minutes per part. Across the 2000-part run, this saved the shop about 75 hours.

In a twist of irony, Paramount Machine machinists Eric Van Orden and Luis Rivas found an advertisement for J.W. Done’s Orbitool in Modern Machine Shop. The pair researched Orbitool and decided to reach out to J.W. Done. After explaining that the part Paramount was producing had four cross-holes with 0.120-inch diameters intersecting a through-hole with a 0.125-inch diameter in L605 cobalt nickel alloy at a 0.0004-inch total tolerance, Orbitool made a tooling recommendation: the P/N 14000D Orbitool 3/32 Double Hemisphere Cutter and the P/N 14000 Orbitool 3/32 Single Hemisphere Cutter.

Removing Only the Burr

J.W. Done says Orbitool functions like a conventional cutting tool, mounting into the toolholder of a lathe or machining center. What makes Orbitool unique is its ability to conduct in-process deburring of cross-drilled holes by using the hemispherical shaped cutter on the end of a flexible shaft.

After inserting the Orbitool deburring tool into a cross-hole, the user moves the tool until the disk contacts the wall of the hole. Once the disk has made contact and the user has tilted the shaft enough for the axis of the tool to reach the diameter of interpolation, the user rotates the tool and feeds it further into the hole using a helical interpolation routine. The attached disk is slightly larger than the cutter to keep the cutter’s abrasive surface from contacting the hole walls until the tool reaches the burr.

Once the tool reaches the intersection between the holes, the disk falls away from the wall, giving the cutter access to the burr. As the disk traces the contour of the cross-hole intersection, the cutter only affects the burred areas. Paramount adds that the flexible shaft enables the deburring tool to remain in contact with irregular shaped features.

Luis Rivas was one of the machinists at Paramount who discovered Orbitool through an issue of MMS. He created the Orbitool’s tool path routine, which led to a net savings of 75 hours for a 2000-part aerospace job.

Photo Credit: Paramount Machine

Clean-Cut Benefits

With J.W. Done’s recommended Orbitool strategies in hand, Rivas created a tool path routine. He used a 40x magnification scope to make minor tweaks and adjustments in the tool path until the initial production process yielded significant reductions in burrs. He took the parts to Martin Loera, the shop’s deburring expert, who agreed that use of the Orbitool and Rivas’ tool path would simplify deburring. Instead of conducting full deburring as a secondary process, Loera would only need to confirm the edge breaks and address a small amount of external deburring.

The changes increased the cycle times on the machine by 45 seconds per part — but decreased the time required in the FOD room by about three minutes per part. Across the 2000-part run, this 2.25-minute reduction saved about 75 hours in total process time.

RELATED CONTENT

-

A Cool Deburring Technique

Ice blasting is a process that uses ice crystals as impact media to remove contaminants. It is popular in Europe for industrial cleaning work because it uses no detergents, solvents or abrasives.

-

When Sophisticated CNC Machine Tools Aren't the Best Answer

As a machine shop owner, challenges come every day. Sometimes, relying on the tools you’re used to can keep you from finding more beneficial solutions.

-

3 Next-Generation Gear Finishing Processes

Vibratory finishing, centrifugal barrel finishing and turbo-abrasive machining are the three top techniques for finishing gears, improving performance and extending service life.

.1692800306885.png)

.1687801407690.png)