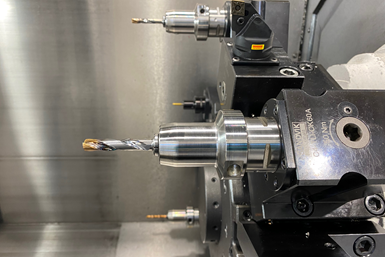

Variables like workpiece material, toolholding quality and machine tool rigidity all affect the tool life of the CoroDrill 860, but head of programming Robert Bird suggests that typical applications for Siemens Energy result in more than 60 minutes of cut time. While this translates to a wide range of between 1,000 and 5,000 holes per drill, even the bottom of this range represents a massive improvement over the cut taps’ 10-20 holes. Photos courtesy of Sandvik Coromant.

Sometimes, making chips is not the right move for machining. Siemens Energy discovered this when it shifted an important job from cut tapping to form tapping, saving a sizable amount of money and as much as 80% of cycle time. The company’s machining division was only achieving around 10-20 threads per tap with its cut tapping tool, a massive efficiency loss when some parts — such as plunger plates — require hundreds of threads. Pre-drilling the holes was also taking longer than expected, at 25 minutes for 12 holes.

“We were breaking taps every part, having to burn them out and hand tap after that,” says Peggy May, CNC machinist at Siemens Energy. Removing these parts from the machine to perform repair work also introduced its own challenges, as even beyond the time spent on repairs, realigning the hole locations afterward was extraordinarily difficult.

Featured Content

Solving this problem took more than a new tool — it took two.

Drill and Tap

Cut tapping creates threads by cutting away the metal in a hole. This operation tends to have problems with chip control and coolant, which can lead to the tool life issues Siemens Energy experienced. As a result, the facility started experimenting with other types of taps for its plunger plate operations, settling on form tapping with Sandvik Coromant’s CoroTap 400.

Form tapping pushes metal together to create threads. Robert Bird, manufacturing engineer at Siemens Energy and the company’s head of programming, says most of the difficulties in form tapping stem from creating the hole, as the drilling tool must hold the hole size even more closely than in cut tapping.

The company turned to Sandvik Coromant’s CoroDrill 860, which provided the stable pre-drilling Siemens Energy needed to create the holes for its 10-24 threads. From there, the company’s machinists could use the CoroTap 400 to create threads with little issue.

While form tapping is not compatible with all of Siemens Energy’s machines, on just the compatible jobs, increases in productivity and tool life saved the facility more than $285,000 in 2022.

Changing the operation was an outsized success with the plunger plates: Drilling sets of 12 holes required only five minutes with the CoroDrill, and the CoroTap 400 creates more than 2,000 threads per tap instead of less than 20. Even for other jobs, the CoroDrill lowered cycle times by around 10%.

Beyond simply producing more threads faster, the change in tooling has also benefited Siemens Energy’s scrap rates. With cut tapping, scrap rate was about 3%, with repair time for removing broken taps bogging down machinists and keeping machines offline. In contrast, Bird reports that the form tapping process reaches a 0% scrap and repair rate.

Between form tapping for the plunger plates and a more general adoption of the CoroDrill 860 across several compatible machines, Siemens Energy boosted its productivity and tool life enough to save more than $285,000 in 2022.

When Siemens Energy first began using the CoroTap 400 in 2021, each tool would last for upwards of 2,000 threads. Since then, the company has tested a newer version of this tool with a radial coolant supply, which enables it to last for more than 6,000 threads in 4140 materials.

Attention to Detail

Beyond the basic differences between cut tapping and form tapping, much of the productivity increase Siemens Energy experienced stemmed from the geometries of the CoroDrill and CoroTap.

The CoroDrill’s polished flutes provide a smooth surface for chip evacuation, while double margins on the cutting edge and backside keep the tool stable. Corner chamfers on the edge of the cutting flute improve the strength of the shape and reduce burrs when the drill exits the hole. Sandvik has also implemented a point-thinning technique that eliminates the need for spot drilling before using the CoroDrill. Edge preparation removes micro defects, increasing cutting edge strength and reducing cutting forces on the tool.

This process also boosts the CoroTap 400’s longevity, but the tap’s through-coolant design has made some of the largest differences, ensuring that the forming operation does not burn off the thread.

Siemens Energy credits much of the success with its recent tooling changes to its Sandvik liaison, Jim Pappas. Pappas is more involved than most company representatives — Bird says that Pappas has his own desk in the Siemens Energy facility and is in the plant four days per week. The pair performed most of the testing for the CoroDrill and CoroTap, optimizing speeds and feeds for high productivity and tool life.

The results almost speak for themselves: “Not only do the products perform as advertised, they’re easy to use and the quality of the tools remains consistent over time,” says Bruce Keesey, CNC machinist at Siemens Energy. “Our run time decreased, and broken taps are now a thing of the past.”

RELATED CONTENT

-

A Higbee Thread Milling Custom Macro

Higbee threads provide a full thread form at the very start of the thread. The sharp edge is removed during the machining process.

-

Reach More B2B Buyers with Thomasnet's Industrial Marketing Services

Tap into 1.4 million engineers, purchasing managers, and procurement professionals sourcing on our platform each month across hundreds of industries with our digital advertising and marketing services, customized for suppliers like you. (Sponsored)

-

How Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

.1692800306885.png)

.1687801407690.png)