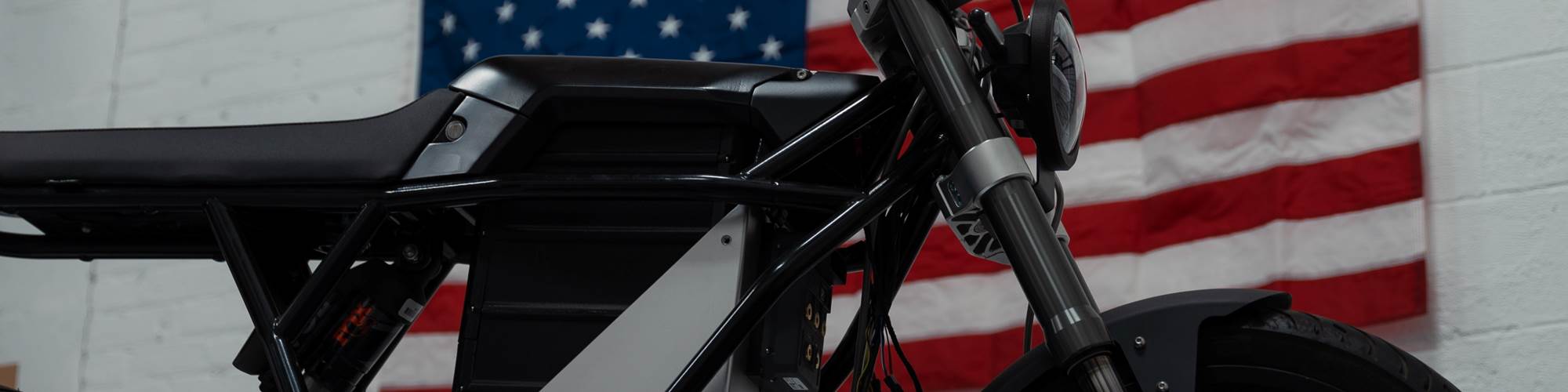

The District, Land Moto's first electric motorcycle, has begun production this year. Photos: Land Moto.

Imagining the future of vehicle production means accounting for multiple overlapping disruptions. Electrification is as much of a change for the automotive industry as, say, 3D printing is for manufacturing. So what will be the new manufacturing system for making these new types of vehicles?

Founder Scott Colosimo holds the portable battery; another is beside him to the right. The easily removable batteries can also be used to power other devices.

Scott Colosimo is going to find out. He has placed himself and his startup venture at the leading edge of this question. Colosimo is the founder of Cleveland, Ohio-based Land Moto, which aims to make electric motorcycles based on U.S. technology through U.S. production, without the buyer having to pay a premium for a bike made domestically. I recently spent time with Colosimo at the Land facility. (His is one of the voices we expect to feature in an upcoming second season of the Made in the USA podcast.)

Featured Content

Land is actually Colosimo’s second motorcycle startup. In 2009, he launched Cleveland CycleWerks. The aim then was similar: manufacture an affordable motorcycle (this one was gas powered) in the United States.

Back then, it seemingly couldn’t be done. Auto-related manufacturers at that time were not interested in the comparatively low production quantities CycleWerks was seeking. So Colosimo turned to China, drawing on his experience with producing there from a previous manufacturing position. Parts makers in China were nimble and responsive, he says, winning his admiration. However, this was coupled to a lack of regard for intellectual property; CycleWerks designs were shared and manufactured without his consent, undercutting the company’s sales. In 2019, he began a side project: prototyping an electric motorcycle with a special feature — an easily swappable compact battery that could be removed for charging or for powering other devices. By 2020, it was a side project no longer; he decided to sell his company so he could launch another focused on this new product, which would call for a new manufacturing network. Colosimo set out again to build a manufacturing base relying on domestic production, and this time he is succeeding.

Electrification is partly why. Relative to a conventional motorcycle, more of an electric bike is solid-state. Less mechanical motion means fewer parts critical to operation. A solid-state gear box for the bike is under development, for example — moves like this remove transmission components from the mix. Meanwhile, auto-industry manufacturers know electrification is coming. Many appreciate they ought to adapt, and some are trying to do so. The latter are open to opportunities to supply parts that serve this emerging need. Land is developing the supplier relationships the previous company producing gas motorcycles could not.

Now, Land is beginning scale production of the District, its debut model. The company will produce at least 1,000 units of the bike in 2022, and likely many more than that. As Land builds up the capabilities and network to perform this, here are some practices (and mindsets) that Colosimo and the Land team are finding valuable:

1. Begin conversations with suppliers all over again.

Success has spared many automotive suppliers from having to innovate or look for new opportunities, Colosimo says. This is changing, but not consistently. Some producers are still locked into existing vehicle part production using dated equipment, he says. But then others see the changes coming — notably EVs changing the auto industry — and they want to be part of it. Some of these are open to the chance to advance together with Land into ramping up a new EV product. The company has been able to start building what promise to be strong relationships with domestic suppliers that might not have taken the company as a customer just several years ago.

2. Rely on 3D printing as an engineering aid.

There is no longer a hard line between design and manufacturing; 3D printing offers the overlap space in which physical iteration of ideas can lead to functional prototypes and initial parts. Land routinely prototypes bike components through 3D printing — for example, an ABS cover for the battery compartment was 3D printed for the first six bikes while Land developed the mold tooling. And it prototypes production tooling this way as well, iterating toward tools that hold components as effectively as possible.

3D printing aids tool engineering. Prototyping precisely the right forms for production tooling saves tooling expense even if 3D printing does not make the final tool.

Can 3D printing ultimately make the final tool or part? A motorcycle offers a challenging application for this. The tooling is often for welding, meaning 3D printed polymer is apt to melt. And on a motorcycle, all production parts are visible. Surfaces need to be attractive, yet print processes delivering this do not also offer economy and speed. Even so — that is, even here in motorcycle manufacturing — 3D printing is vital for speeding engineering and keeping tooling and prototyping cost low.

3. Control tooling cost; avoid tooling where possible.

Land will keep improving its bike design and the battery that enables it. “Technology is changing so fast, we’ll probably never make 60,000 of the same bike,” Colosimo says. This means tooling aiming at production quantities greater than this is wasted expense. Launching an old-style motorcycle model could have entailed $3 to $4 million in tooling investment, he says. The design and production of an EV has to be different. A larger proportion of components on Land’s bikes will be made through processes without dedicated tooling, including parts machined from solid or made through CNC laser cutting.

4. At every pain point, vertically integrate.

New features and advancing technology mean the bike design is apt to frequently change. Favoring machined or laser-cut parts allows for this by minimizing tooling.

This practice is probably the most vital part of Land’s domestic manufacturing strategy. The supplier base around the company still does not offer a means to obtain rapid, affordable, low-quantity work, so Land invests in its own capability wherever this is needed. For example, 3D printing is a no-brainer; the company prototypes as needed by printing on its own machines. A machining center for tooling and short-run production was the investment that came soon after this. In-house laser cutting might be next. “Wherever we hit a pain point where we can’t get the part we want when we want it, we look to developing the capability in-house,” Colosimo says, coming to recognize that some significant component of U.S. production will need to be in-house.

Indeed, some “pain points” are the aches from an earlier time. Colosimo ultimately expects to expand Land’s facility to vertically integrate battery production. The battery is crucial to Land’s success and key to what makes the product distinctive. Keeping manufacturing very close will safeguard IP, protecting today’s business. Meanwhile, it will also assure tomorrow’s business by allowing Land to innovate quickly — refining the battery within its own facility, to advance this disruptive element of the product as far as that disruption might go.

Peter Zelinski writes about manufacturing technology and how it is changing. Find more of his work related to CNC machining and additive manufacturing. To suggest an article topic related to a success in your manufacturing facility or business, or a technology development you are close to, email him here.

RELATED CONTENT

-

An Introduction to Superfinishing

Learn what superfinishing is, what applications it should be used for and why you should take care when specifying surface finish parameters.

-

Supply Chain Woes Yield Opportunities for Manufacturers

As companies scramble to build more robust supply chains, manufacturing events are aiming to help North American manufacturers find new opportunities.

-

SolidCAM Wants to Help Machine Shops Get into Additive Manufacturing

SolidCAM's partnership with Desktop Metal is aimed at making additive manufacturing more accessible to job shops and other manufacturers.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=970;quality=90)

.1692800306885.png)

.1687801407690.png)