Monaghan Reaming System Provides Long Service Life

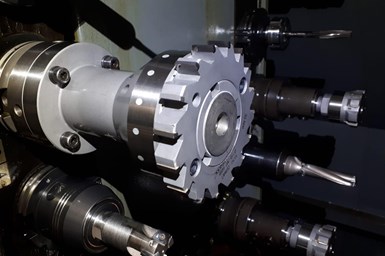

The Diatool Top Speed Ring modular reaming system features multiblade design with uneven spacing of cutting edges to create round and cylindrical bores.

Monaghan Tooling Group’s Diatool Top Speed Ring (TSR) modular reaming system is said to achieve up to 70% faster feed rates compared to standard cutting rings, according to the company. With up to four additional cutting blades, this specialized design enables faster machining and increased tool life to achieve leading performance and cost efficiency. The multiblade design features uneven spacing of cutting edges to create round and cylindrical bores. The TSR comes set to size and requires no additional setup, delivering ready-to-cut functionality. The holders are equipped with internal coolant as a standard feature.

The Diatool Top Speed Ring covers a diameter range of 50 mm to 225 mm (1.9685" to 8.8583"), making it an optimal solution for a diverse range of precision reaming applications. Monaghan Tooling Group says it is ideal for long production runs of large diameter bores, precision reaming of heavy equipment components or any application requiring precise and repeatable bore sizes.

Designed for durability, the solid TSR offers straight- or left-hand-fluted options, providing the optimal bevel lead geometry for performance and chip control throughout its extensive service life. It also supports cermet, carbide or PCD blades, as well as a full line of coating options, enabling optimum reaming results across a variety of part materials. The Top Speed Ring holders are available in cylindrical shanks or module connections to enable runout compensation or use with standard hydraulic holders.

In addition to long service life, the Diatool TSR has rings that can be reconditioned numerous times to OEM specifications, achieving the same tool life as a new reamer.

RELATED CONTENT

-

Allied Machine & Engineering Expands Range of Boring Tools

Both the 420 (410) and 465 (464) digital boring heads come equipped with a 3ETech docking port for easy digital diameter adjustments.

-

Walter Extends Line of Precision Boring Tools

The new boring tools employ modular components such as cartridge holders and extensions, which are matched to the system, utilize an extensive range of indexable inserts suited for precision boring and can be used for all material groups.

-

Allied Machine Cartridges Mount to Custom Boring Tools

ES-Bore cartridges fit on existing custom tool bodies and replace current lay-down cartridges.

.1692800306885.png)

.1687801407690.png)