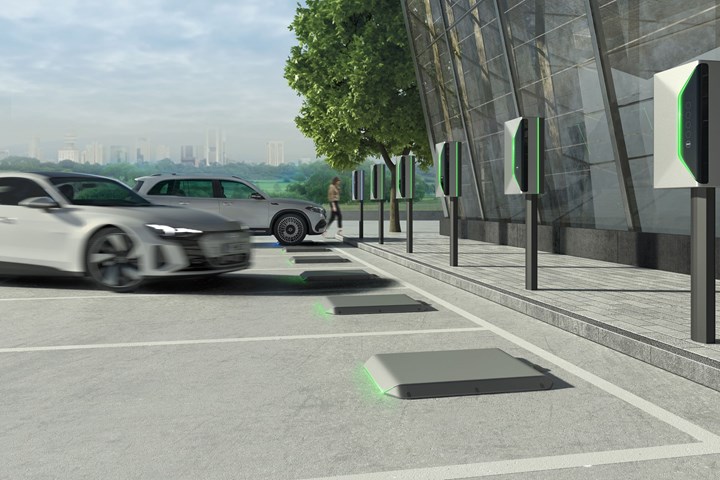

Siemens and Mahle Partner to Develop Wireless EV Charging

Mahle will contribute its experience as an automotive supplier and Siemens will use its expertise in the field of charging infrastructure to develop wireless charging stations for electric vehicles.

Siemens and Mahle have signed a letter of intent to collaborate in the field of inductive charging of electric vehicles. “Wireless charging of electric vehicles is emerging as a major market for the future. In addition to making life considerably easier for drivers, who no longer have to fiddle with cables and connectors, it is a crucial requirement for the autonomous mobility of tomorrow. The transfer efficiency of wireless, inductive charging is comparable to plug-in systems,” Stefan Perras, head of pre-development and innovation for charging infrastructure at Siemens AG, says.

One aspect of the planned cooperation includes coordinated standardization efforts in the relevant pre-standardization and standardization bodies. The goal is to close gaps to ensure full interoperability between vehicles and the charging infrastructure, according to the companies.

In addition, there are plans to exchange ideas about developing a complete inductive charging system for electric vehicles. Mahle aims to contribute its experience as an automotive supplier and Siemens its expertise in the field of charging infrastructure.

Both parties are also planning extensive interoperability and cross-testing between the charging equipment on the vehicle (secondary coil) and the charging infrastructure (primary coil). This will reportedly enable for technical improvements and validation of inductive charging systems for electric vehicles and ensure interoperability. Some of the testing will be performed as part of publicly funded projects.

As a full-service provider for eMobility charging infrastructure, Siemens eMobility offers a complete range of charging hardware, software and services — from residential to commercial to depot applications. “Siemens’ core expertise in smart buildings and smart grids makes us uniquely positioned to meet our customers’ needs with comprehensive solutions and to help them design, install and manage sustainable charging solutions for a better future,” Perras adds.

RELATED CONTENT

-

Ford Partners With Rockwell Automation to Advance EV Program

The companies will jointly collaborate on assembly tooling designs and architectures that will increase speed to market.

-

Understanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

-

Evolution of Performance Camshaft Grinding, Finishing

Comp Cams has made numerous improvements to its CNC camshaft grinding process. The company has also implemented what it calls its “Micro Surface Enhancement” finishing technology, which works in tandem with its enhanced grinding process to further improve camshaft longevity and durability.

.1692800306885.png)

.1687801407690.png)