The Automated Shop – A Conference and a Goal for U.S. Machine Shops

Modern Machine Shop’s upcoming technical conference will be an opportunity to learn about several types of automation that are now accessible to small- and mid-sized machine shops in the U.S.

#thesetup

This coming October 10 and 11, Modern Machine Shop will host TASC – The Automated Shop Conference. This technical conference is targeted toward small- and mid-sized machine shops (50 employees or fewer) on or about to take the journey toward lights-out machining and automating mid- to high-volume production.

I’ve had the chance to start thinking about a major question related to the conference: How do the shopfloor automation capabilities at large OEMs differ from those available to small and mid-sized machine shops? For context, I’m writing this column after having just returned from an extended tour of Renishaw’s three main production facilities in England and Wales. These are highly automated facilities, and I left the multi-day tour with a few impressions relevant to this question.

Featured Content

Renishaw is known widely as a provider of metrology systems as well as spectroscopy equipment and metal 3D printers. Across its three main production sites, the company typically machines 1.2 million parts per month. Every 30 days, Renishaw processes about 4,000 individual work orders or batches and performs around 2,800 machining operations via automated setup with no manual inputs. On top of that, the company is about to debut a new software platform designed to leverage data from connected shopfloor devices and push automation even further.

The result of these efforts, according to the company, is that its automation cells connected to the new software platform have a scrap rate of 0.22%. At its largest production plant in Miskin, Wales, the company staffs only four people per shift to oversee 43 automated machine tools.

So then, what is the difference between the automation deployed by Renishaw and the automation available to small and mid-sized machine shops?

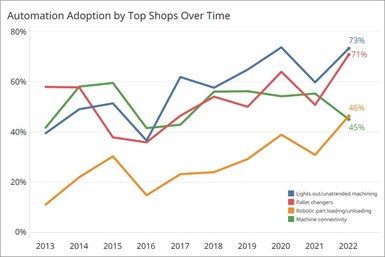

Adoption trend among Top Shops for each of four forms of automation. Almost all trend up over time. Credit: Gardner Intelligence

The answer is that there is no difference — at least not from a pure technology perspective. Except for Renishaw’s new software platform, I did not see evidence of shopfloor automation at Renishaw that could not be implemented at a typical U.S. machine shop today.

The key differentiator is that Renishaw has a team of engineers dedicated to innovating and implementing new automation solutions to use in its own production processes. Can the average small- or mid-sized U.S. machine shop afford to hire a team of engineers to execute automation strategies? Of course not. But shop leaders can consult their peers.

This is why the time is now for an automation technology conference like TASC, where industry specialists will share their own automation strategies, and where shop owners and managers can learn from each other and focus on automation solutions that make sense for their operations. Through Modern Machine Shop’s Top Shops benchmarking data, we already know that this country’s top performing small- and mid-sized shops are automating, although in some cases not at the same levels at larger shops. What’s more clear is that higher levels of automation are associated with higher performance.

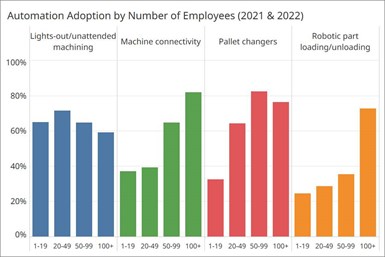

Distribution of plant sizes among adopters of each of four forms of automation. Small shops are adopting automation, some forms more than others. Credit: Gardner Intelligence

During a recent conversation with Matt Kirchner, the president of ATS/LAB Midwest who will co-chair the TASC event with me this October, Kirchner put it this way: “As somebody who was chief executive of a contract manufacturer for more than a decade, I know what it's like to get up every morning and have to figure out how to run my plan,” he said. “And the last thing I'm thinking about are the technologies that are going to disrupt me five years from now. I'm just trying to get parts out the door and adjust quality issues and manage my team. But the truth is that in the same way that technologies and advancements like standardized quality and approaches like Kaizen revolutionized manufacturing 10, 15 or even 30 years ago, that's the kind of disruption we're seeing now. We have to get ahead of it.”

Registration for the TASC event in Novi, Michigan will open later this spring. In the meantime, if you’d like to learn more or submit an application to present at conference, visit tascevent.com.

RELATED CONTENT

-

Increasing OEM Visibility to Shopfloor Operations for the Win

A former employee of General Motors and Tesla talks about the issues that led to shutdowns on factory lines, and what small- to medium-sized manufacturers can do today to win business from large OEMs.

-

Team Unity – the Tightrope Walk for Corporate Culture

Finding your place in an organization doesn’t always mean falling in line. But creating a culture of continuous improvement means fostering unity among independent thinkers.

-

There's Your Waste, Shaw! An Argument for Shop Reinvestment

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

.1692800306885.png)

.1687801407690.png)