Buying a Five-Axis: Picking Options and Add-Ons

So you’ve settled on a five-axis machine. So what options do you choose? One to remember: spindle probing.

#Basics

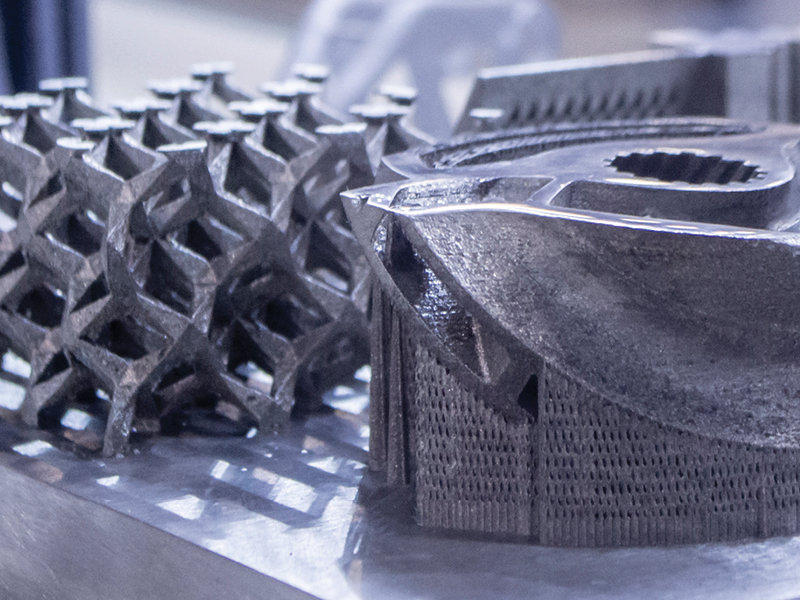

Generally speaking, five-axis machining is complex and requires a lot of expertise and substantial investment, not only in the machine itself, but also in CAM and simulation software. Some machine builders also offer the required software, but others do not. With some machines, it is included as part of the standard package; with others, it is an option at an added cost. Many customers jump into full five-axis machining only to discover later that the CAD/CAM and simulation software were not included in the initial package.

Options such as 3D cutter compensation are also available. This option enables the user to insert a tool offset into the control, say 0.002 inch, rather than change each tool-diameter setting. For years, you couldn’t use cutter compensation once the program rotated one of the axes. Today’s cutter-compensation software will keep the tool center point right on the surface, no matter which axis is moved or rotated.

Featured Content

Offline simulation software contained in a high-quality CAM software package can be extremely helpful to verify a five-axis machining process and avoid collisions, as it can be difficult for a programmer to mentally visualize all possible collision points among the tool, fixture and part when working in five axes.

Spindle Probing: An Added Reason

Whereas spindle probing on a three- or four-axis horizontal machine is highly recommended, spindle probing on a five-axis machining center is compulsory. Although probing is used to automatically set fixtures and multiple work offsets; locate the part precisely without the need for expensive fixtures; and obtain other benefits, there’s yet another reason for a spindle probe on a five-axis machine:

A spindle probe is the quickest, most repeatable and most accurate method for establishing centers of rotation for the rotary axes and tables, trunnions, or programmable C axes relative to the center point of the cutter. To define the exact location of this point in space, appropriately called a pivot point, an offset value (like a tool offset or work offset) must be applied to control parameters. A probe determines this offset precisely. The probe will also help compensate for any pointing error the machine spindle or table may have. Once this point is defined, all axes are then relative to the center point of the tool.

The pivot point is normally set using a known artifact and a calibration routine, a process that automatically maps the entire machine. This artifact data is then analyzed to derive a compensation value that is uploaded to the control. Periodically, the calibration routine can be quickly run and the values checked to see if movement in any of the five axes has occurred.

This is part four of a four-part series about buying five-axis machine tools.

- Part one: The Value Proposition of Five-Axis Machining.

- Part two: Buying a Five-Axis: The Costs and Benefits of a Complex Machine

- Part three: Buying a Five-Axis: Selecting the Right Machine

Find more insights about acquiring a new machining center by visiting the Techspex Knowledge Center, “Guide to Buying Machine Tools.”

RELATED CONTENT

-

Four New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

-

Advanced CNC Milling and Drilling Quiz

A provider of machine shop training offers these questions for benchmarking metalworking knowledge.

-

Sometimes the Trickiest Part of CNC Machining Is Holding the Part

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining cell.

.1692800306885.png)

.1687801407690.png)