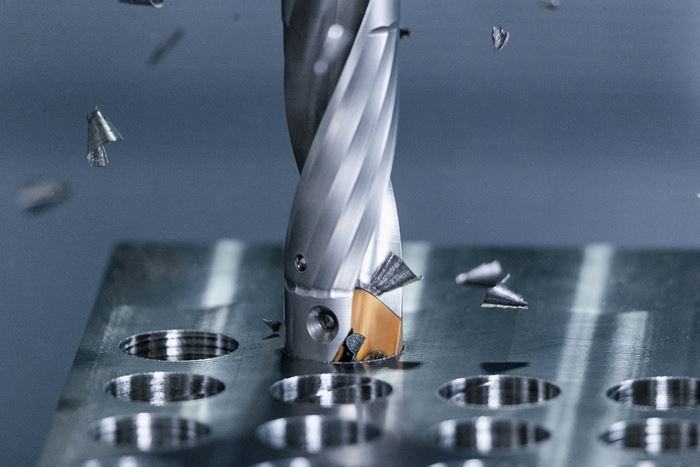

Whether it’s using drills to make holes, borings bars or reamers to enlarge their IDs, or taps to thread them, this is where to read up about holemaking. Holemaking is a process used to cut a hole in a part or a workpiece.

How to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Holemaking: Essential Reading

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Choosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

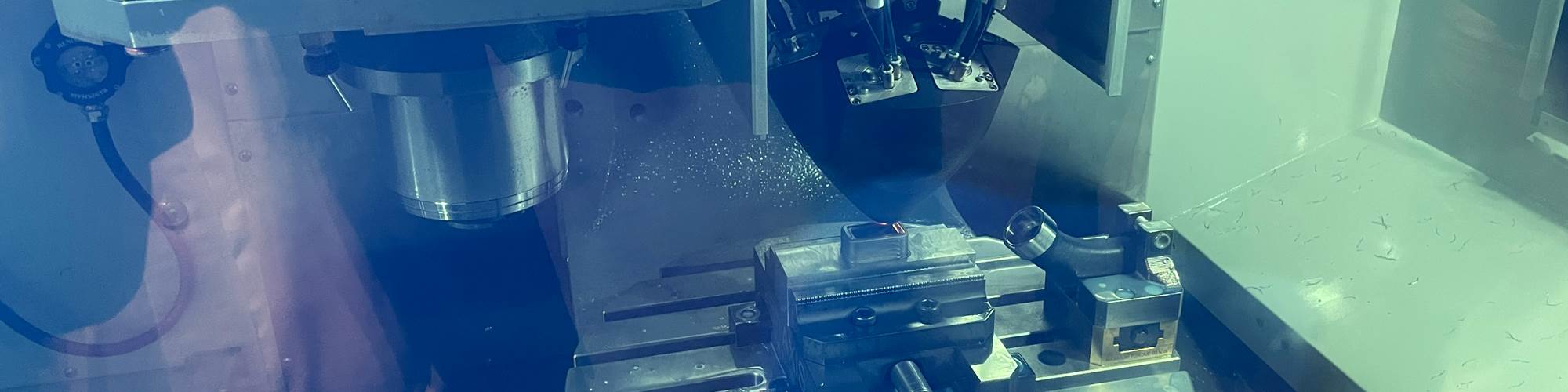

Cutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

How to Choose the Best Drill Type for Your Next Job

Five questions to ask when deciding between solid carbide drills or replaceable insert.

How to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

FAQ: Holemaking

What Are Carbide Coatings?

Most modern carbide inserts and solid carbide tools are coated with a thin film (between 3 and 20 microns, or 0.0001 to 0.0007 inch). The coating is typically composed of titanium nitride, aluminum oxide and titanium carbon nitride layers. This coating increases the hardness and creates a heat barrier between the cut and the substrate.

Source: Choosing Your Carbide Grade: A Guide

What is a counterbore?

Counterboring is a machining operation that will enlarge an existing hole’s diameter to a specified depth. Traditionally, counterboring is done with either a special counterboring tool that has a pilot, or it is done with an end mill. In either case, the diameter of the tool (end mill or counterbore) must match the diameter that is counterbored.

Traditional counterboring is great for smaller holes, but as holes get larger, the cutting tools get more expensive.

Source: Custom Macro To Helically Mill A Counterbore

What is countersinking?

A countersink is a functional surface upon which a fastener head bears. Because fastener performance is so important, countersink tolerances are critical.

What is a chamfer?

Hole chamfers are usually specified simply to make it easier to insert a screw, pin, bushing, or other assembly component. The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance.

Source: Gaging Countersunk And Chamfered Holes

Holemaking Suppliers

Narrow by Holemaking Category

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

Kennametal Drill Lineup Offers Extended Application Range

The Drill Fix Pro is designed for extended tool life and smooth drilling at high metal removal rates, with outboard inserts that feature a wiper geometry for smoother surface finishes and larger coolant channels for high-volume flow.

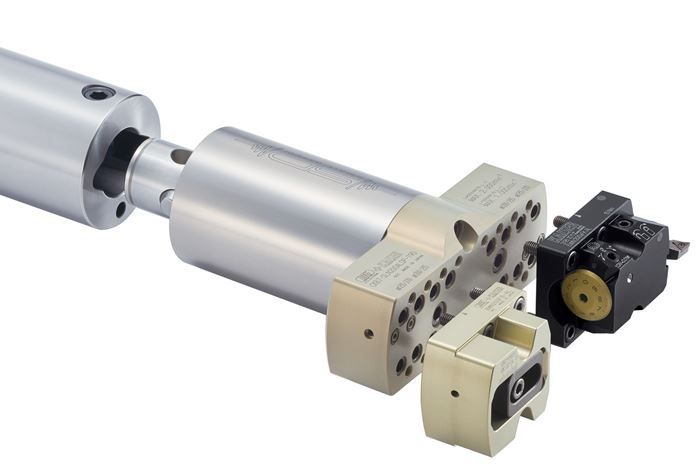

Monaghan Reaming System Provides Long Service Life

The Diatool Top Speed Ring modular reaming system features multiblade design with uneven spacing of cutting edges to create round and cylindrical bores.

Tungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Walter Drilling Inserts Provide Extended Tool Life

The P6006 indexable inserts are said to be ideal for holemaking without a pilot drill up to 10×Dc.

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

Tungaloy Counterboring Tools Feature New Cutting Inserts

The new AH6225 grade features a high-hardness, titanium-rich PVD coating, combined with a tough dedicated carbide substrate.