Data-driven manufacturing implies that decisions controlling the manufacturing process should be based on facts, not guesses, wishes, theories or opinions. Emerging technology is enabling both people and equipment to collect and process the facts they need to achieve better results. Driving manufacturing with data promotes integration and coherence across manufacturing organizations throughout the supply chain.

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Data-Driven Manufacturing: Essential Reading

How to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

How to Scale a Job Shop for Growth with Fewer People

Front office disorganization and poor shop floor communications don’t just reduce a job shop’s efficiency; they are a barrier to growth. Having the right kind of ERP system can be the key to improving profitability and scaling for future growth

4 Ways “Tag and Track” Technology Keeps Data Chains Intact

Scannable images and tags inextricably link relevant information with workpieces, cutting tools and other physical assets.

5 Smart Drilling Lessons Apply Beyond the Application

A specific machine learning use case illuminates general principles for applying artificial intelligence at any CNC machining business.

How To Find The Right Solid Carbide Tool For Your Production

Watch this demo for an inside look at Sandvik Coromant’s advanced solid carbide tools like CoroDrill 860-GM – designed for fast and problem-free drilling, maximizing productivity through high metal cutting efficiency. (Sponsored)

FAQ: Data-Driven Manufacturing

How do you choose an ERP system for a data-driven machine shop?

- Consider your objectives and requirements.

- Measure return on investment (ROI).

- Speak to fellow ERP users.

- Scrutinize the demo.

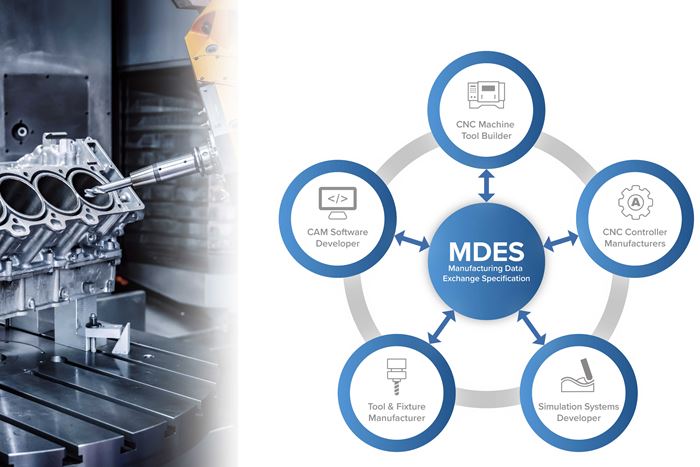

How does “tag and track” technology keep data chains intact?

- Streamlining workflow.

- Automating and verifying tool setups.

- Managing the tool crib.

- Reducing waste through productivity improvement.

What are some of the best practices for manufacturing cybersecurity?

- Training regularly

- Requiring strong passwords

- Requiring multi-factor authentication

- Monitoring for threats

- Consider security beyond virtual security

Data-Driven Manufacturing Suppliers

Narrow by Data-Driven Manufacturing Category

- Calibration Software

- ERP for Make-to-Order Mfg

- ERP for Standard Mfg

- Job Estimating Software

- Manufacturing Execution Systems (MES)

- Quality Documentation

- Accounting Software

- Database Management

- Software, Other Manufacturing

- Statistical Data Collection & Analysis

- Tool Crib Control

- CAD/CAM Software

- CAD/CAM for Additive Manufacturing

- Engineering Analysis & Simulation

- Machinability Databases

- NC Program Optimization

- NC Verification

- Nesting Software

- Post Processors, Stand-Alone

- Tool Design

- Robot Controllers

- Programmable Logic Controls (PLC)

- Memory Units

- Machine Monitoring

- Identification Systems

- Direct or Distributive Numerical Control (DNC) Systems

- Digitizing/Scanning Systems

- Digital Readout (DRO) Units

- CNC Units

- CNC Software, Stand-alone

- Communications Networks & Data Transmission Equipment

Digital Solutions Dominate TIMTOS

At TIMTOS, many OEMs highlighted solutions designed to overcome challenges that may sound familiar to U.S. manufacturers.

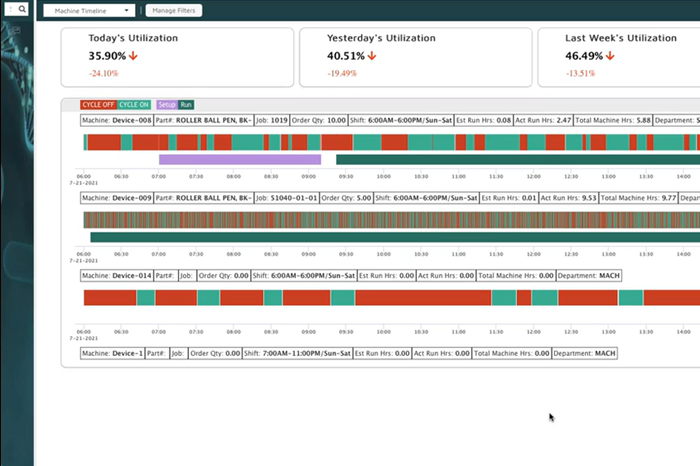

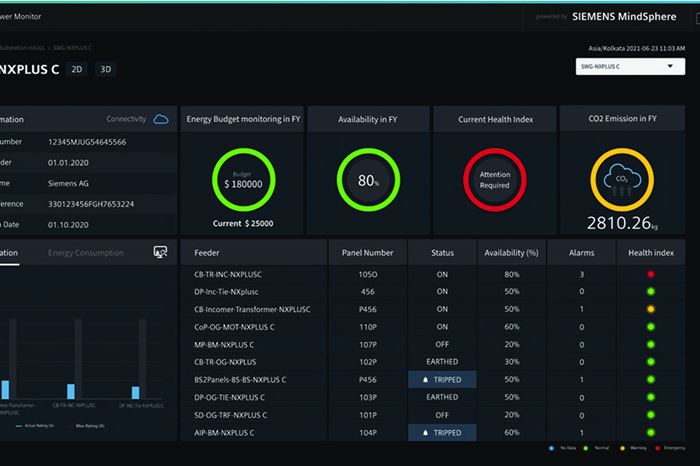

Machine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Ceratizit's Control System Increases Process Security

Eastec 2023: The ToolScope monitoring and control system can reduce cycle times up to 15% and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

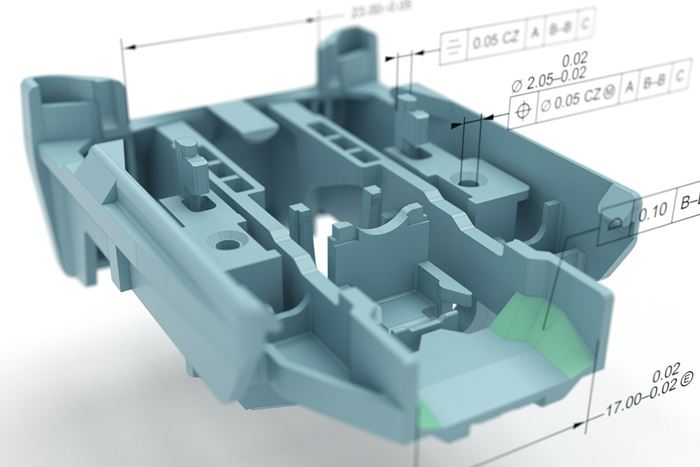

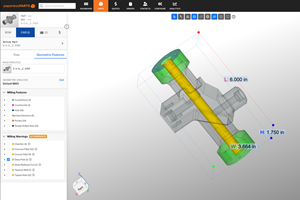

Paperless Parts Quoting Platform Streamlines Estimating Process

Eastec 2023: Recent updates to Paperless Parts include performance enhancements to the 3D Part Viewer that improve the ability to navigate complex parts and assemblies.

EAC's IoT Platform Connects Shop Floor With Actionable Data

PMTS 2023: The ThingWorx platform establishes a single source of data for collecting, aggregating and enabling secure and easy access to data for different job roles at multiple locations.

#pmts

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

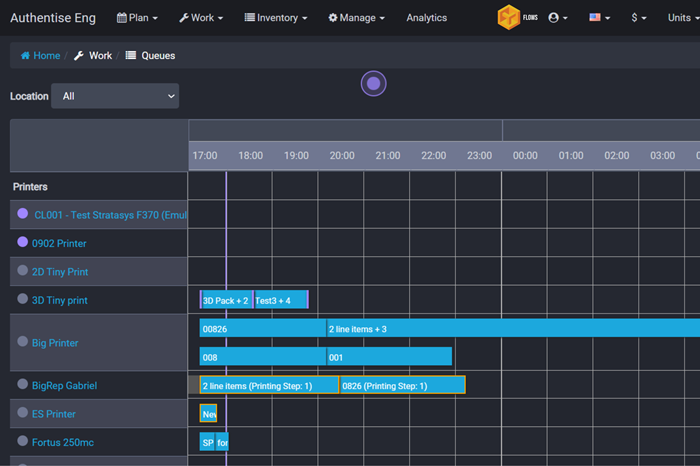

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

#workforcedevelopment #zaxis