Deburring is perhaps the most critical post-machining operation for ensuring the functionality of the machined part, as well as the safe handling of the part. Deburring has traditionally been a task that takes place after machining to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

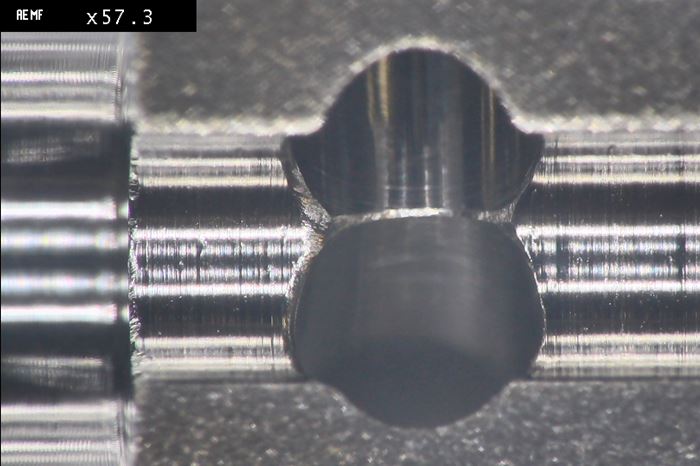

Controlling Burr Formation within Small Intersecting Holes

A reader struggles with burrs between intersecting holes 1 mm and less in diameter. MMS Online’s micromachining expert offers advice.

Deburring: Essential Reading

What is the Best Process for Micro-Deburring?

Various techniques address the challenge of getting a clean machined feature at microscopic scales.

Deburr Small Parts With Swarming Stainless Pins

This deburring system uses magnetism to excite small pins that remove light burrs from small, non-ferrous parts.

A Cool Deburring Technique

Ice blasting is a process that uses ice crystals as impact media to remove contaminants. It is popular in Europe for industrial cleaning work because it uses no detergents, solvents or abrasives.

4 Considerations for Electropolishing Machined Parts

Manufacturers considering this non-contact finishing process should expect test runs and close collaboration with service providers before production begins.

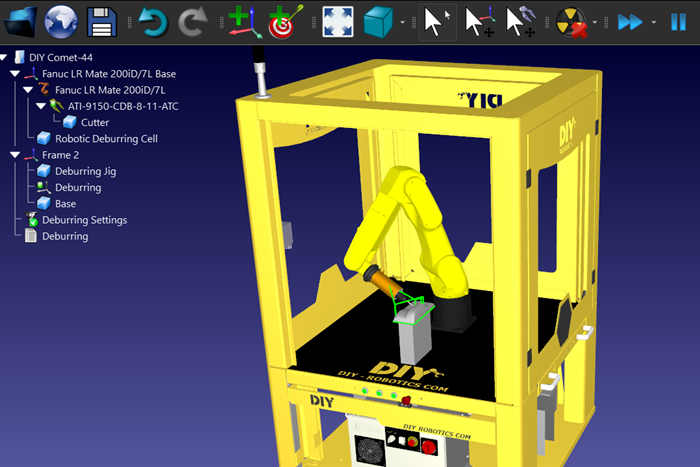

ATI Offers Deburring Blade Suitable for Automation

The pneumatically controlled, articulated design of ATI Industrial Automation’s Compliant Deburring Blade (CDB) enables users to tune the contact force to accommodate specific applications by changing the air pressure.

FAQ: Deburring

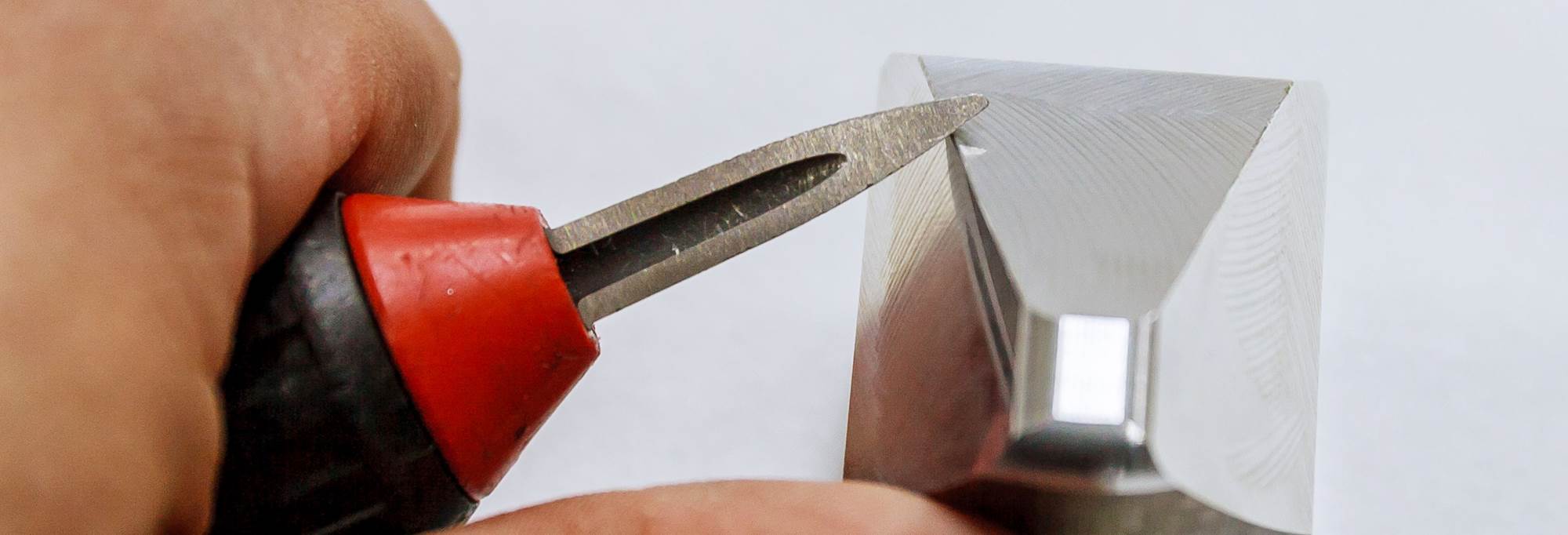

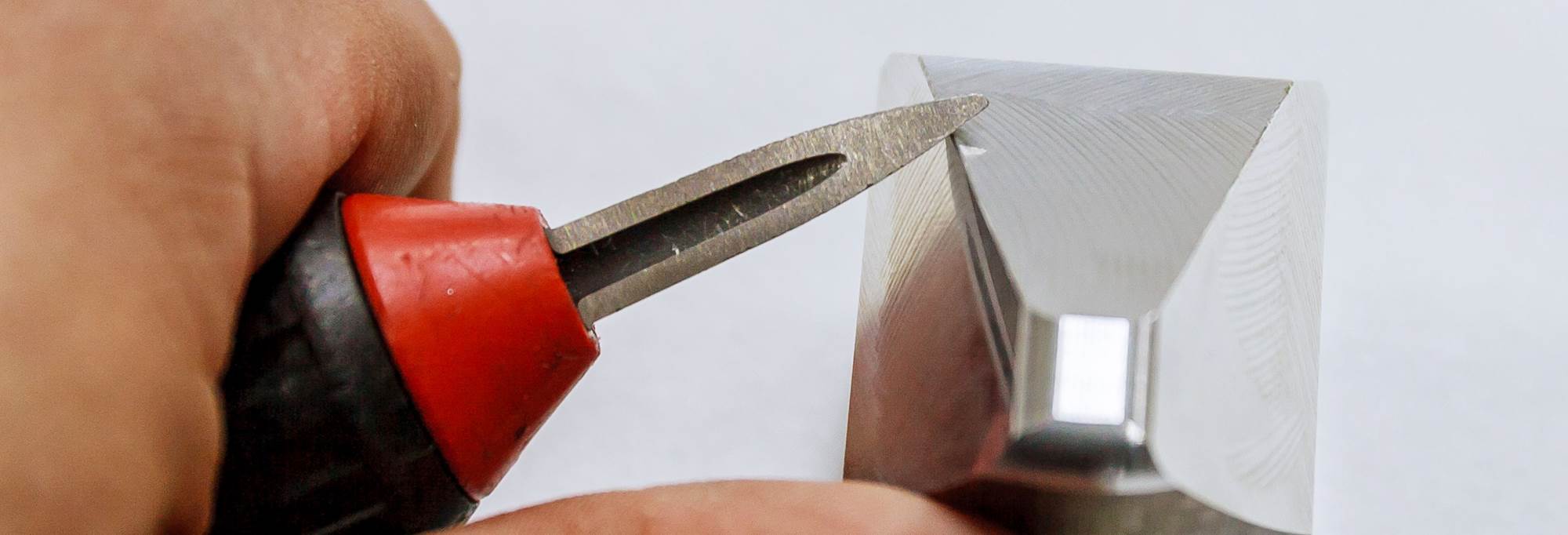

What is deburring?

Deburring has traditionally been a manual task that takes place after machining to remove any remaining sharp pieces of metal.

What is a deburring tool used for?

A deburring tool is used to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

Deburring Suppliers

Narrow by Deburring Category

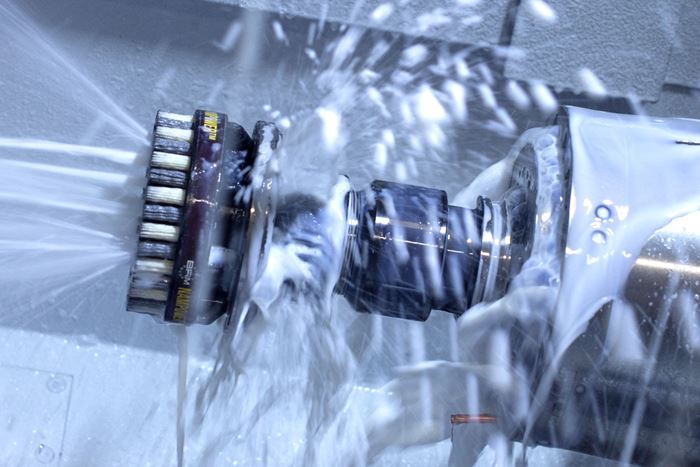

Automated Part Deburring, Cleaning in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

#Basics #partscleaning

Drilling and Chamfering Tool Solves Machine Shop's Vexing Problem

An oil & gas part with a lot of holes required that Utex use two different tools to ensure burr-free inner and outer diameters. With Heule’s Vex-S tool, the shop realized time savings per cycle of an entire minute by performing drilling and chamfering in a single step.

#casestudy

4 Considerations for Electropolishing Machined Parts

Manufacturers considering this non-contact finishing process should expect test runs and close collaboration with service providers before production begins.

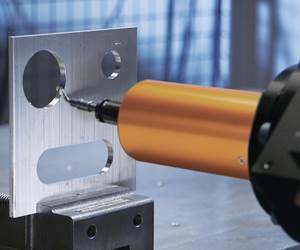

ATI Offers Deburring Blade Suitable for Automation

The pneumatically controlled, articulated design of ATI Industrial Automation’s Compliant Deburring Blade (CDB) enables users to tune the contact force to accommodate specific applications by changing the air pressure.

April 2019 Product Spotlight: Cleaning and Deburring

This month’s Modern Equipment Review Spotlight focuses on equipment used to remove imperfections from and clean finished workpieces.

#partscleaning

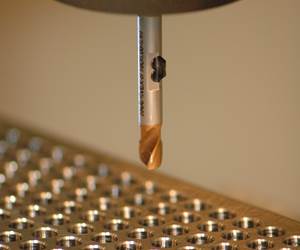

Carbide Burrs Make Smaller, Granular Chip Breaks

Designed for surface removal on demanding production runs, Saint-Gobain Abrasives’ line of Norton double-cut carbide burrs is said to last longer with fewer change-overs on challenging production applications.

Tool Speeds Cross-Bore Deburring

IMTS 2018: Heule Tool’s COFA deburring tool is designed to provide front and back deburring on even and uneven surfaces.

#imts