Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

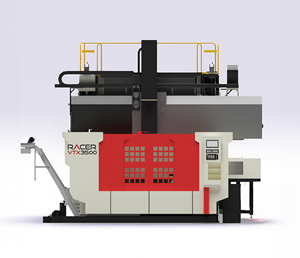

Racer Machinery Lathe Enables Full Ram Travel

The VTX machine series features programmatic indexing of the Y-axis, enabling for extended height to accommodate taller parts.

Kaast Grinding Machine Handles Large Workpieces

The R-Grind HD cylindrical grinders are able to accommodate workpieces up to 31" × 156" and/or 4,400 lbs.

Edge Technology Sliding-Headstock Lathe Boosts RPM

The FMB Turbo 3-38 for sliding-headstock CNC lathes provides superior bar pushing and stock support in the transition zone between the bar feeder and lathe spindle.

.jpg;maxWidth=970;quality=90)