Greenleaf End Mills Provide High Metal Removal Rates

Westec 2023: Xsytin-360 end mills provide high material removal rates and result in increased productivity on a wide range of materials.

Greenleaf Corporation highlights its Xsytin-360 end mills — a tool that combines the company’s phase-toughened Xsytin-1 substrate with a specialized cutting geometry that is said to offer 10X higher productivity — in booth 3101 at Westec 2023. The strength of the material enables the user to apply chip loads similar to solid-carbide end mills with higher speeds common to ceramic machining. These new ceramic end mills provide increases in productivity over current solid carbide or ceramic products.

Greenleaf says its Xsytin-1 material is engineered to machine a wider variety of materials than any other ceramic in the industry. The structure of this phase-toughened ceramic exhibits high wear resistance and outstanding thermal shock resistance, which makes the Xsytin-360 end mills highly predictable, versatile, high-performance products.

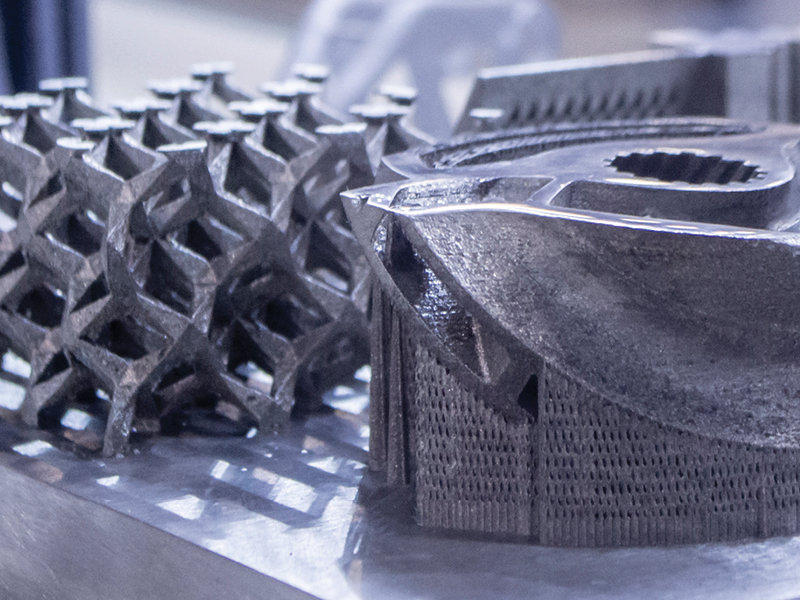

Xsytin-360 end mills provide high material removal rates and result in increased productivity on a wide range of materials. These end mills are effective at machining a variety of materials, including high-temperature alloys, 3D-printed sintered high-temperature alloys, hardened steels, ductile cast irons and compacted graphite iron (CGI). In hardened steels, the tool life of Xsytin-360 end mills has proven to be equal to high-performance carbide end mills when run at high-end speeds (11,460 rpm), while also removing over 73 in3 (over 1200 cm3) of material. Xsytin-360 end mills are ideally suited for machining materials in the aerospace, automotive, die and mold and power generation industries.

RELATED CONTENT

-

Trumpf Deburring Tool Provides Repeatable Accuracy

The TruTool TKA 1500 edge milling tool is now available with a new cutting mount and guide fence for increased applications and safety.

-

Sandvik Coromant End Mills Feature Specialized Coating

The new CoroMill Plura HD solid end mills, featuring a Zertivo 2.0 coating, are said to improve tool life, process security and productivity over previous versions.

-

OSG End Mills Provide High-Efficiency Milling

The company has expanded its range of end mills with two offerings for high-speed milling.

.1692800306885.png)

.1687801407690.png)