Managing Coolant with Skimmers, Refractometers and More

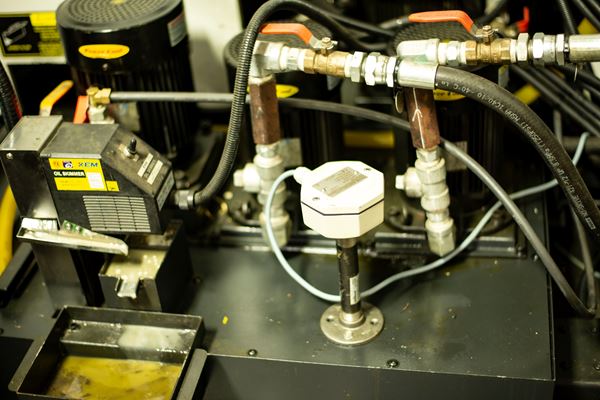

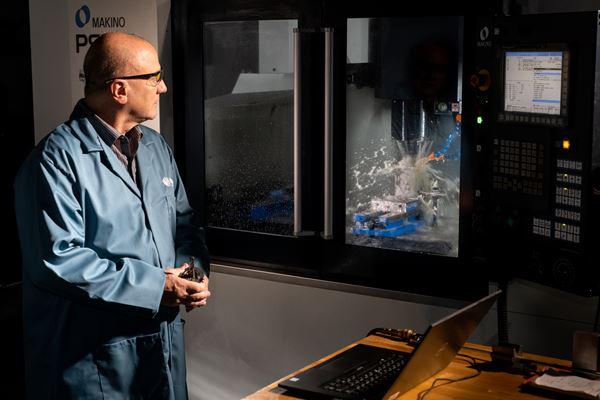

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Evan Doran

Associate Editor, Modern Machine Shop

Vomat Coolant Filters Provide Precise Temperature Control

The company’s filters ensure a continuous supply of clean oil for microtool grinding applications.

Hennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.

STLE Hosts Co-Branded Tribology, Lubrication Events

The 2023 STLE Tribology Frontiers Conference and Tribology & Lubrication for E-Mobility Conference will provide attendees with two opportunities to share and learn the latest tribology and lubrication engineering science.

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Biodegradable Lubricants Eliminate Cleanup Costs

Bio-Air Tool Lubricants perform in many applications, offer better natural lubricity than petroleum-based oils and are safer for employees and the environment.

168 Manufacturing's Coolant System Automates Delivery

PMTS 2023: FullShop systems monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low.